Mantels en Bodems

- Mantel onder inwendige druk

- Elliptische bodem onder inwendige druk

- Torisferische bodem onder inwendige druk

- Klopperbodem (DIN28011) onder inwendige druk

- Korfboogbodem (DIN28013) onder inwendige druk

- Hemisferische bodem onder inwendige druk

- Vlakke (cilindrische) bodem onder inwendige druk

- Vlakke (niet-cilindrische) bodem onder inwendige druk

Flenzen

Bepalen van Vormspanningen

|

Tips en Tricks Actuele ASME Code calculatie workshops in: |

|

Januari 2024 ASME Code Essentials (engels) Februari 2024 ASME Code Weken (engels) |

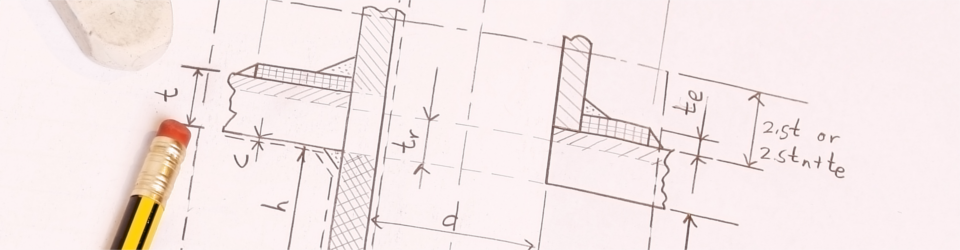

Berekening mantel inwendige druk

bar

mm

mm

N/mm2

-

Tussenresultaat

Resultaat

I [App.1-1(1)]

nodige wanddikte treq:

ontwerp marge:

II [UG-27(1)]

nodige wanddikte treq:

ontwerp marge:

III [App.1-2(1)]

nodige wanddikte treq:

ontwerp marge:

IV [App.1-2(1)]

nodige wanddikte treq:

ontwerp marge:

Invoerfout

Notes

ASME Code Section VIII, Division 1, 2017 Edition offers four different formulas for the internal pressure design calculation of cylinders. The results slightly differ depending on the formula used. It´s up to the user to select the formula. It must be noted, however, that formulas I and II from UG-27 and Appendix 1-1 (Supplementary Design Formulas) can only be applied for thin walled cylinders, while formulas III and IV are applicable for both thin and thick walled cylinders.

As is usual with all ASME Code formulas, the dimensions used have to be considered for the corroded condition. Corrosion allowances (and tolerances) have to be added to the results. The allowable stresses are listed in the ASME Code Section II, Part D. For pressure bearing components which are to meet the ASME Code requirements, only these allowable stress values or those from approved Code Cases are permitted.

The correct efficiency factor E for longitudinal seams (Category A) are determined according to paragraph UW-12. Brief instructions for the determination of the correct efficiency factor are available in our ASME Code Tutorials (German).

The basic rules are as follows:

- no radiographic examination (RT): E = 0,7

- spot RT: E = 0,85

- full RT: E = 1, except adjacent category B or C butt welds do not meet spot requirements according to UW-11(a)(5)(b) and are not type 1 or 2 welds (half-apex angle is equal or less than 30 deg) – in this case E = 0.85

- seamless vessel sections and heads: E = 1, except adjacent category B or C butt welds do not meet spot requirements according to UW-11(a)(5)(b) or are Type No. 3 (single welded butt joint without backing strip), 4, 5, 6 (full fillet lap joints) or 8 (angle joints larger 30°) - in this case E = 0.85

If you have further questions please contact us directly or start a discussion in our ASME Code Forum. To stay informed about any changes and amendments to our websites, upcoming seminars and the latest information about the ASME Code, please feel free to subscribe our newsletter.

These calculation tools are intended to be used for information and guidance only, they do not replace a detailed design calculation and compliance with all applicable Code requirements. CIS GmbH expressly disclaims liability for errors and omissions in the contents of this site.

ASME Code Essentials (Online)

ASME Code Essentials (Online) Uitwisseling van Ervaringen

Uitwisseling van Ervaringen ASME Code Weken 2024 (Online)

ASME Code Weken 2024 (Online) EN

EN DE

DE BE

BE FR

FR